Anatomy of a Consulting Job

Many potential clients contact me each month asking what the format is of a consulting job. The answer is always that there is no set format; every client has different needs. A job helping an older roasting company implement and use modern roasting software is quite different from one teaching a new company how to set up and operate a roastery. I'd like to describe here one version of a typical consulting job working with a new roaster.

Background

Over the past few months, I’ve been working with Color Roasters, a new company in Eagle, Colorado. I met the owner, Charlie Gundlach years ago when he worked at Portola Coffee Lab in Costa Mesa, CA, and ran into Charlie many times over the last few years while he was working as a barista at Boxcar Coffee in Boulder, CO.

Charlie and his family set up a roastery/cafe in Eagle, a small ski town in Central Colorado. Eagle is a lovely town, but rather quiet half the year, so Charlie is focusing on building a wholesale business in addition to running the cafe.

To my mind, Color is much of what a good cafe should be: the staff is well-trained and the coffee is great, from the quality of the green, to the roasting, to the careful extractions. Color has also taken a cue from the “Australian cafe model," and offers a simple, well-executed cafe-food menu. Color is as good as the best cafe in some American cities.

Charlie hired me after building the bar, just before he was ready to roast. I advised him on where to buy his first green coffee and we arranged to start up his new Probat P12 together, remotely, through FaceTime.

The first roast day

Prior to roasting together, I had advised Charlie on how to warm up his roaster. Once the roaster was warmed up, we got on FaceTime and I walked Charlie through seasoning his roaster with a few darkly-roasted batches of cheaper green. While roasting those batches, I was able to observe the quality of the burner flame and the “cigarette-lighter airflow test” (see The Coffee Roaster’s Companion) with various air damper settings, and to adjust the settings on his Cropster graphs.

We used the seasoning batches to learn how to interpret the P12’s manometer readings and decide on the best gas settings. Every installation’s ideal gas settings will vary somewhat, and the only way to dial them in is to observe a few roasts. Eagle is at an altitude of 6,601 feet (2012 meters), which made me more careful than usual about assuming what settings would work well.

The ROR curves of our second and third seasoning batches already looked like competent roasts, so by the time we loaded some more expensive coffee, we were already producing what I was certain was very drinkable coffee.

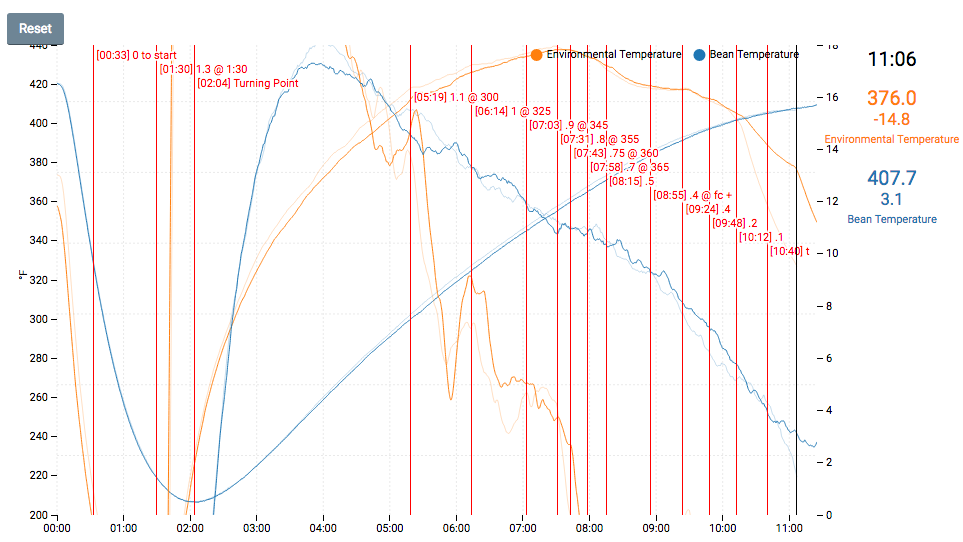

Here is the curve of our fifth batch, a Colombian Cauca purchased from Red Fox:

We had chosen to roast 15-lb batches (7kg) exclusively, and on the Series-2 P12, I’m comfortable roasting 15lbs in about 10:00. At Color, our first few roasts finished a little faster than I’d hoped, but I was very pleased with the ROR curves and wasn’t concerned about underdevelopment.

The next couple of months

Charlie and I consulted, sporadically, by email over the next couple of months. We’d look at Cropster curves together and make a tweak here and there. My primary advice during that time was to take baby steps to slow down the roasts while maintaining straight ROR curves.

In a typical consulting job, I prefer to smooth a client’s ROR curves before tasting their coffee. That may seem odd, but if a new client sends me something like a crash-and-flick ROR curve (or worse), I know roughly how it will taste, and I know that we will make massive improvements in the first hour of consulting. (If you’re teaching someone to cook, and his or her first effort is raw on the inside and burnt on the outside, you probably don’t need to taste it to know what advice to give.)

Regardless of how these first roasts taste, my initial approach is often the same: show the client how to smooth the ROR curves. Once the RORs are smooth, we’re ready to work on nuance. Given that Charlie’s ROR curves were straight on day one, I was keen to taste the coffee right away. Surprisingly, that fifth batch of Cauca was one of the best five roasts I tasted from anyone in 2016.

The Second Visit

My friend Lee Safar is the mastermind behind Elixir Specialty Coffee. Lee had asked me to roast the batches for her Christmas Elixir subscription, and I wanted to do that for her, but I don’t currently own a roasting machine. Given that I was in Colorado for all of October and November, I decided to offer Charlie a deal: we’d spend a day working on his roasting together at no charge, in exchange for his allowing me to roast some of his coffees for Lee’s upcoming subscription. Charlie was keen, so I went to Eagle last weekend after the season’s first snowstorm blanketed Colorado in white. It was a spectacular drive from Boulder to Eagle.

I had asked Charlie to install an environmental-temperature probe (ET probe) before my visit, as the P12 doesn’t come with a digital ET probe as a standard feature (Dear Probat: WTF?). Charlie’s handyman delayed the job twice and Charlie had managed to install the probe only the night before my visit. That posed an unexpected challenge, as did the fact that we roasted early in the morning when it was freezing outside, whereas Charlie had only thus far roasted during warmer afternoons.

We had two problems that morning: the first was that Charlie’s typical warm-up procedure clearly wasn’t adequate, given that freezing air had been wafting down the roaster’s chimney and into the machine all night. Even after a warm up twice as long as Charlie’s standard, it turned out the machine still wasn’t up to its equilibrium thermal energy, as the first two roasts were a little sluggish. Our second problem was that the new ET probe somehow was interfering with the BT probe readings in Cropster, adding noise and volatility that had never been there before.

Note that Charlie's 100+ roasts prior to installing the ET probe all had rather noise-less ROR curves, and all the roasts after installing the ET probe had the degree of noise seen above.

I want to pause here and offer a little insight into being a consultant: the scariest part of my job is to travel to a client to roast on an unfamiliar machine with its own unique gas settings, chimney configuration, probes, and other quirks. I can’t count how many machines I’ve encountered that have had installation mistakes, inappropriate manometers, software-connectivity problems, or poorly placed bean probes. At every job I want to help the client meet his or her roasting goals in a day or two, sometimes even in a few hours, on a machine I’ve never seen before. I always find that first hour with a new machine a little stressful until I get comfortable with its quirks. In the past year I’ve set up a new system to prevent day-one surprises by asking each new client for lots of information, photos, and sometimes videos of his or her machine. Surprises still occur, but much more rarely.

By the third batch Charlie and I had gotten the machine warm enough, and we resigned ourselves to the new noise in the Cropster data. We roasted a few bathes each of an Ethiopian Hamacho Waeno and Colombian Familia Camayo, both from Red Fox. (I’d score the coffees 86 and 87, respectively.) The Ethiopian was abundantly floral and winey, though its mouthfeel and juiciness weren’t top notch. The Cauca had a lovely, creamy mouthfeel, with a fair amount of delicate acidity. On a whim, i decided to brew a Fetco batch of the coffees as a 50/50 blend, and it proved to be delicious. I can’t even remember the last time I blended coffee for a batch brew.

The Consult

After our initial 2-3 hours of online consulting, Charlie was already roasting better than 90% of US third-wave roasters. During the last two months, Charlie spent time cupping countless green coffees, getting comfortable experimenting on his machine, and mastering Cropster. During our session we didn’t need to tweak much, but we did work on slowing the roasts down a bit more, and now that we had an ET curve to work with, we worked on smoothing the arc of the ET curve to give us more control over the BT ROR around first crack. We also worked on a few tricks to prop up the ROR after first crack and to prevent any risk of an ROR flick at the end of a roast.

Try the Coffee!

The coffee Charlie and I roasted together will be available soon as part of Elixir’s Christmas offering. If you’ve never tasted Elixir, it’s time you do. I don’t think I have the words to do it justice, but if I had to try, i would say it tastes a little like the cleanest, crispest cold brew you can imagine, but with the delicacy of oolong tea, and a faint hint of whisky.

You can also buy a bag of these batches from Color Roasters, on sale this week.

*I have no financial interest in the sale of these coffees by Elixir or Color. I’m merely noting these sales to support their wonderful products, and to give a few curious readers the option to taste what I think are pretty good roasts.

Thanks for reading.