WHY ROASTER AUTOMATION IS NOT YET A SUCCESS

Many people wonder why roaster automation is not better or easier. I’d like to discuss the current state of automation and the difficulty of creating successful automation. I define “success” as having identical results in the cup, such that a panel of expert tasters would not notice a material difference among several batches of a coffee roasted using automation.

I define full automation as a system in which the roasting machine manages the settings in an attempt to match a reference curve. This is distinct from semi-automatic systems such as Cropster Gas Control and Replay Assist, the Probat Pilot system, etc., which change gas settings at bean-temperature triggers based on preset recipes.

For clarity, Loring offers both systems: “profile roasting,” which is full automation, and “burner recipe” which is semi-automation.

Successful full automation requires:

An effective warmup and BBP. I’m a little tired of machine manufacturers claiming that *their* machines don’t require an effective BBP. Sure, it’s possible one of those manufacturers has rewritten the laws of physics, but it’s much more likely they have low tasting abilities or low standards for consistency, or their marketing departments are just dishing out BS.

A very well tuned PID.

Ideally, a fluid bed (Sivetz, Neuhaus Neotec, Typhoon) or indirectly-heated machine with recirculation (Loring, IMF, Brambati). Full, precise automation is always going to be more difficult in classic drum roasters due to the slow responsiveness of heavy metal drums combined with our current inability to measure drum temperature reliably.

Let me give some examples of why automation systems are not as precise as they seem at first glance. These examples are from roasts using Loring automation (profile roasting) with a competent BBP. While Loring has made the best attempt so far at full automation, I personally would not use it yet. These examples show that the best automation system out there still needs work. Of course, if these examples did not involve an effective BBP, they would look and taste even less consistent.

These are two 60kg Loring batches that followed a series of 20kg batches. The blue curve was the first of the 60kg batches, as astute readers would assume. The graph shows that the machine’s thermal energy was lower before the blue batch, which was to be expected, given that the previous batch was 20kg, and few roasters know how to create a successful “transitional BBP” when changing batch sizes (which is emphatically necessary, even with Loring.) These curves could have conceivably been identical with a proper transitional BBP, but those are 1) difficult to work out and 2) needing one brings into dispute the false claim that one can switch between batch sizes at will and the Loring automation will keep churning out identical batches (of a given batch size) regardless of those changes.

These two batches of course tasted noticeably different.

In the example above, at the very least, the PID should have used more gas, and kept it at 100% sooner and longer, in the blue roast, at approximately 1:30. Note that most of the time, when the automation chooses 100% gas, it is saying “I’m playing catch-up with the reference curve” which means it is usually not replicating the reference curve.

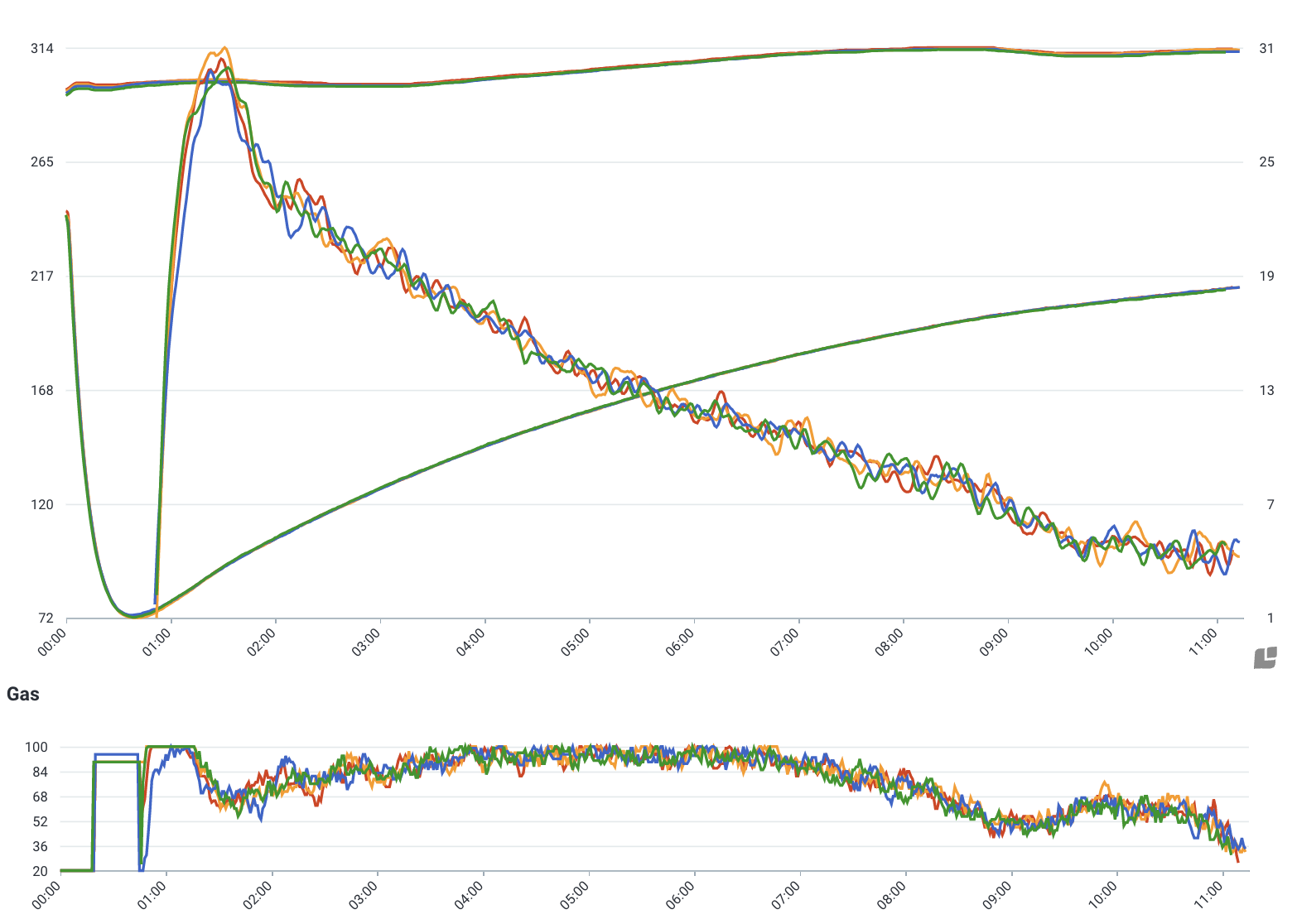

Here is an example of four batches using Loring automation. As you can see, replication was obviously more successful here. Factors that probably improved the replication were that the BBP was effective and didn’t have to compensate for a change in batch size, and the inlet-temperature curve was more consistent. That doesn’t guarantee consistent results, but it is an important piece of the puzzle. If we had better data quality from the first minute of each batch, I suspect the replication would look a little less successful,

Here is an example of excellent replication by a competent human roasting manually

Let’s up the stakes and look at replication of 9 consecutive batches by a competent human roasting manually. Note that some of the (very minor) discrepancies below came from changing the recipe in an attempt to improve results (in other words, intentional inconsistency, as you can see in the purple gas curve). The cup results were as consistent as the curves

Should you use full automation?

That depends on your standards. If your standard is “I don’t mind a small drop in quality and consistency to have a more labor-efficient system” then using it may make sense. If you say “the automation is more consistent than I am” then it also may make sense. Though in that case I’d prefer you seek a consultant to improve the consistency of your manual roasts (hint: choose the person who coined the term “between batch protocol” and developed the first truly successful BBP in the industry.)

Personally, I think more people should use semi-automatic (burner recipe) systems. Such systems are also labor efficient, but when combined with an effective BBP will generally yield more consistent, and likely tastier, coffee than the currently available automation systems.

The day will come when roasting automation is better than a competent human, but that day has not yet arrived.

I would rank the current state of roasting systems like this:

Best: competent human or competent human programming a semi-automatic system

Good: full automation

Bad: Not-so-competent human or not-so-competent automation

Cannot ever work consistently: any system that excludes an effective BBP

Thanks for reading.