How to Choose a Roasting Machine

If you’re in the market to purchase a coffee roaster, I wrote this book for you. I’ve had the fortune to roast on hundreds of machines throughout my career, and I’d like to help new roasters buy the right machine for their needs. My goal in writing this book isn’t to tell the reader which brand to buy, but to help the reader to understand the important considerations in the decision and to make an educated choice that suits his or her needs.

Most machines from the major brands are capable of roasting a delicious batch of coffee, but some machines have features that make top-quality roasting and replication too difficult, even in skilled hands. Common examples of such features include thin, single-walled drums, slow gas valves, valves with poor resolution at low settings, excessive insulation around the drum, slow or poorly positioned probes, and limited control of roasts after first crack.

When seeking advice about what machine to buy, please ask those who have experience with all of the major brands. Roasters who have used only one or two machines tend to favor those machines and lack perspective about other machines. It should go without saying, but please do not rely on the advice of roasting-machine sales associates, as they are always biased, and often misinformed about the virtues of competing brands.

I do not publicly recommend or critique particular brands in this post, as those opinions are best shared with clients in private. Here, I will discuss what to consider when choosing a roaster. It’s up to readers to infer my opinions of various brands.

Budget

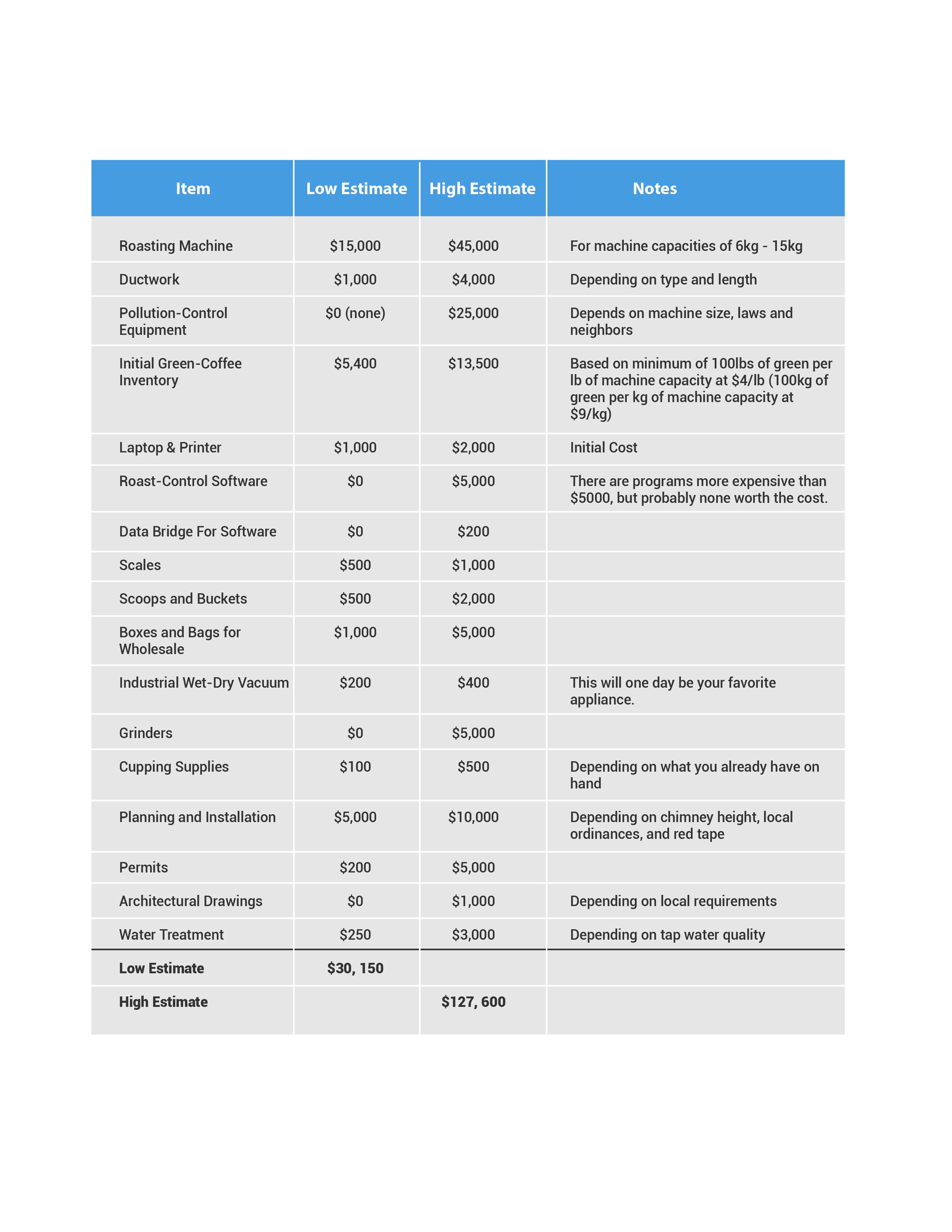

First, consider how much you can afford to spend on a roaster. When calculating your budget, don’t forget to include the cost of necessities such as chimney ductwork, pollution-control equipment, initial green-coffee inventory, QC equipment, a laptop for logging roast data, and various supplies. A budget should also include the costs of installation, permits, and architectural drawings for the permit process.

If you’re a first-time roaster buying a machine with a capacity of between 6 kg–15 kg per batch, I’ve offered current (2020) equipment cost estimates below. Costs will vary country to country; I’m most familiar with the costs in the US, so I’ve referenced those here.

All prices are in USD; I’ve attempted to offer reasonable low and high estimates for each item. If an item’s low estimate is $0, it means the item is optional. I haven’t bothered including optional equipment such as color readers and other QC devices, as they are not critical for a roasting startup.

Key Considerations

With your budget and the above costs in mind, consider how much you can spend on the roasting machine. If you can afford it, please buy a larger roaster than you think you need. I’ve never known a roaster to regret buying a machine that was a bit too large, but I’ve known many roasters who regretted buying machines they quickly outgrew. Once you’ve estimated the startup costs of your roasting operation, prioritize your wants and needs.

1.CapacitY

To choose the proper machine size, it’s important to estimate how much coffee you expect to roast each week over the next two years. Note the weekly amount of coffee you expect to roast two years from today. I recommend buying a machine large enough to roast that quantity of coffee in no more than 25 hours. When performing these calculations, remember that a machine’s real capacity is likely less than its stated capacity, and that beans lose 14%–20% of their weight during roasting. (For reference, third-wave roasts lose approximately 14%, while a Starbucks roast may lose 20% or more.) A machine’s burner capacity—not its drum size—determines how much coffee it can roast well. A reasonable guide is to assume that a quality roast of one kg of green coffee requires 11,500 kj/hr (or, one lb of coffee requires 5,000 btu/hr).*

*This formula does not apply to machines that recirculate hot air back into the roasting chamber. Recirculation machines have higher capacity relative to burner output.

Your roasting-machine salesperson will likely claim that you can roast 15 kg per batch in a 15kg machine. The job of a salesperson is to sell machines, not to help you roast the best-possible coffee, so take any claims lightly. The salesperson may be technically correct, because the drum can surely fit a 15-kg batch, but a full batch may take 15:00–20:00 to roast, which is longer than ideal. If quality roasting is your goal, it’s usually safe to assume you will roast 3–3.5 lf batches per hour at 50%–70% of a machine’s stated capacity. Then deduct the 14%–20% weight lost per batch to calculate how much roasted coffee per hour a machine can produce.

For example, if one were to roast three and a half batches of 7 kg green coffee per hour in a Diedrich IR-12, with an average weight loss of 15%, the machine would produce just under 21 kg of roasted coffee per hour (3.5 * 7 kg * .85 = 20.8 kg). That’s more realistic than assuming the machine will roast 48 kg per hour.

2. Reliability

Some machines are more reliable than others. Machines with fewer parts, fewer high-tech features, and heavier builds tend to be more durable and reliable. Older, simpler roasters, such as the fabled UG-series Probats are examples of rugged, low-tech machines built to last. Of course, all design decisions entail tradeoffs. Some modern technology may lack reliability but make quality roasting easier and more repeatable. Again, ask other users about reliability before buying— I’m sure most roasters would be happy to share their experiences, especially if they have complaints! While roasters are not always objective about their own roast quality, they tend to be somewhat objective about the reliability of their machines.

3. Service

Many brands may not offer service or support in your country. Further, some companies offer poor support once you have paid for your roaster. I won’t publicly discuss which companies, in my experience, neglect their customers, but I implore you to ask other users of a brand about service quality before you put a deposit on a machine. Even if you have a pleasant initial sales experience with a company, that does not guarantee future service quality.

4. User Interface:

This may seem like a trivial consideration, but if you’re going to spend 20–40 hours per week using a roaster, a well-designed user interface is important. The interface isn’t just about convenience and comfort, it can also affect roast quality and repeatability. For example, machines that require you to repeatedly tap an up- or down-button to change the gas setting can be tedious and slow to respond. In comparison, a machine with an analog gas dial or a smart touchscreen is more responsive, makes it easier to replicate curves, and can be a pleasure to operate. Other ease-of-use considerations involve having large, well-positioned digital manometers, timers, and temperature readouts.

5. Aesthetics

You may want to consider aesthetics if you are installing a machine for use in a retail cafe or other public space. A beautifully refurbished vintage machine may make a nicer impression than a budget, modern machine.

6. Machine Configurations

I discussed this topic in detail in The Coffee Roaster’s Companion, but will repeat the basics here. Common architectures include classic-drum roasters, indirectly fired roasters, recirculating roasters, and fluid-bed roasters. Each design has pros and cons.

Classic drum roasters: In these machines a drum rotates above a gas flame, and a fan pulls hot air from the burner through the drum and out of the roaster. Most smaller machines are classic drum roasters. Classic drum roasters get the job done, though many models provide too much conductive heat transfer, due to having a thin single-walled drum or an improper distance between the burner and drum. If too much heat is transferred to the beans via direct contact with the drum, coffee will taste harsher and less delicate. If you choose a classic drum roaster, I suggest you seek a machine with a double-walled drum and a burner with sufficient btu/hr (or kj/hr) for your needs. Compared to other designs, classic drum roasters offer good thermal stability but slower responses to gas changes.

Indirectly heated drum roasters: In these machines the burner chamber is separated from the drum and hot air passes from the burner chamber through the drum. The design allows the drum’s surface to remain cooler because the flame is not in contact with the drum. Indirectly heated roasters are more difficult to control than classic drum roasters, because they require skillful management of airflow, while classic drum roasters rarely require much, if any, airflow adjustment.

Recirculation roasters: These machines recirculate a portion of the roasting exhaust air back through the burner and roasting chamber. Such machines are energy-efficient but often run the risk of imparting smokey or polluted flavors on coffee. To avoid smoke taint, it’s important to heat the recirculated air to a sufficiently high (afterburner-level) temperature before passing it through the drum.

Fluid-bed roasters: These machines rely on a bed of rising hot air to circulate the beans and keep the beans aloft. Fluid-bed roasters eliminate the risk of conductive-heat damage, and are usually capable of developing beans well in short amounts of time. While there is no theoretical downside to fluid-bed roasters, in practice their control systems are usually too simplistic to fulfill the machines’ potential. Given the current, rapid evolution in roast-control and data-logging software, I expect the utility and popularity of fluid-bed roasters to grow rapidly in the near future.

7. Features

None of the features listed below are necessary to roast a good batch of coffee, but each may contribute to improved roast quality or repeatability.

Double drum (applies only to classic drum roasters) and powerful burner: The foundation of a good classic drum roaster is its burner and drum. As noted previously, burner output determines a machine’s true capacity. Double drums allow for faster and hotter roasting with less risk of tipping or scorching. Make drum quality and burner output your first two concerns when choosing a classic drum roaster. You can easily replace or upgrade fans, valves, ducts, etc, but you cannot easily replace a drum, and upgrading a burner can be expensive.

Variable-speed-drive (VSD) fan: As long as your roaster’s fan provides a reasonable amount of draw, you don’t need a variable-speed fan to produce good roasts. But without a VSD fan, it’s impossible to maintain consistent airflow levels day to day. The combination of a digital air-pressure manometer and a VSD fan is essential for expert-level roast repeatability.

Air manometer (aka drum-pressure manometer): A manometer in the duct between the roasting drum and exhaust fan is a relatively new, worthwhile addition to a roaster. The manometer reads pressure, not flow, but that pressure reading correlates with airflow. Using the same fan setting every day does not ensure consistent roasting because airflow may vary day to day with the weather and other factors. Having an air-pressure manometer helps one know how to adjust the fan to provide consistent airflow every batch. (Note: directly measuring airflow requires installing probes in the exhaust duct, but the probes get dirty too quickly during roasting to work effectively. Using an air-pressure manometer is the best current option to monitor and maintain consistent airflow batch to batch. However, the relationship between pressure and flow will shift slowly as the ducts get dirty, so frequent chimney cleaning is critical.)

High-resolution gas manometer: Most roasting machines come with small, cheap analog manometers that offer imprecise gas-pressure measurements. I recommend replacing your stock analog manometer with a high-resolution digital manometer. Analog manometers may be aesthetically pleasing, but they make discernment of precise readings too difficult.

Proper probes and probe locations: To be a great roaster by today’s standards, one needs better green, lighter roasts, quality data collection, precise controls, and software to track and analyze the data. To ensure adequate data collection, insist on having a bean probe and an environmental probe, each with diameters of 2.5 mm– 4 mm. An inlet-temperature probe is helpful but not critical.

The optimal bean probe location in most machines is as follows:

The probe’s tip should be 3–5 cm from the inside of the machine’s faceplate.

The probe’s tip should be 3–5 cm from the inner drum edge. (2 cm is ok for machines with capacity of 1 kg or less.)

The probe tip should be in the heart of the bean pile, even when roasting very small batches. If the probe is too high in the drum or too close to the center axle, it may not be immersed in the bean pile of very small batches. Proper probe location should provide quality data for batches as small as 20% capacity.

Paying for a machine: Manufacturers typically require the buyer to deposit 50% of the machine’s price upon ordering, with the balance due upon shipment of the machine. The problem with such arrangements is that once a manufacturer has your deposit, he or she may lose motivation to deliver your machine on time. Salespeople routinely promise a machine in three months, secure a deposit, and then ship the machine six to nine months later, claiming unavoidable delays. The buyer is helpless as he or she pays rent on an empty roastery and loses money waiting for the machine to arrive. I have seen such delays happen on fully half of my clients’ orders. I strongly suggest insisting on a sales-contract clause guaranteeing delivery by a certain date, with a penalty against the manufacturer for late delivery.

Given the number of considerations listed above, how should one prioritize them when purchasing a machine? Here is how I would prioritize the list:

Ensure a brand’s machines are reliable.

Seek out features that assist in precision roasting.

Find a company that offers prompt, reliable service, with service representatives based in your country.

Cost (relative to burner output and features)

Other considerations discussed above, such as installing a better probe or manometer can often be arranged with the manufacturer or added after you receive a machine.

The Bottom Line

When choosing a roaster, I suggest you determine your budget, make a prioritized list of your needs and wants, and ask other roasters about their experiences with various machines. Trust others’ opinions about machine reliability and service, but be skeptical of their opinions about roast quality unless they have had extensive experience on numerous models of roasters. Ignore subjective information from salespeople. When possible, arrange with the manufacturer or another roasting company to spend a few hours working on a model of machine before committing to its purchase.

Notes about accessories:

Floor scale: Please choose a sturdy floor scale with a resolution of no more than 0.005 kg (0.01 lbs) and a maximum capacity greater than the weight of your largest batch plus the bucket in which you will weigh that batch. You may want a scale with even larger capacity if you plan on blending together full batches. The scale’s resolution must be precise enough to provide useful weight-loss calculations.

Timer: Your software or roaster’s control panel probably tracks roast time, so you shouldn’t need a separate timer. If you do need one, make sure it is easy to read from a distance.

Spotlight: I recommend mounting a lamp with a full-spectrum bulb just above the bean trier. While I recommend using the trier sparingly, it should be well-lit for those rare times you use it.

Fire-suppression: I recommend hard-plumbing a water line into the roasting-machine faceplate and chaff collector. The water line should include a spray head with an easy-to-access valve. This is probably the best insurance you can have against a roaster fire.

Small accessories list:

Please consider this list a starting point; it is not comprehensive.

Large scoop for green coffee

Large scoop for roasted coffee

Buckets for green coffee

Separate, larger buckets for roasted coffee

Bucket labels and markers

Tables or counters for weighing, bagging, and boxing

Empty bags and boxes

Heat sealer

Wet/dry vacuum for cleaning chaff collector

Brush for chimney cleaning

Rags for wiping oil from buckets and cooling bin

Knife and/or scissors for cutting open green-coffee bags

Commercial dishwasher (if you can afford it)

Cupping supplies

Packing tape

Label printer

High-temperature, food-grade silicone (for resealing pipes after cleaning)

Grease for bearings

Flashlight

Photo Credit: Andrew Rizer